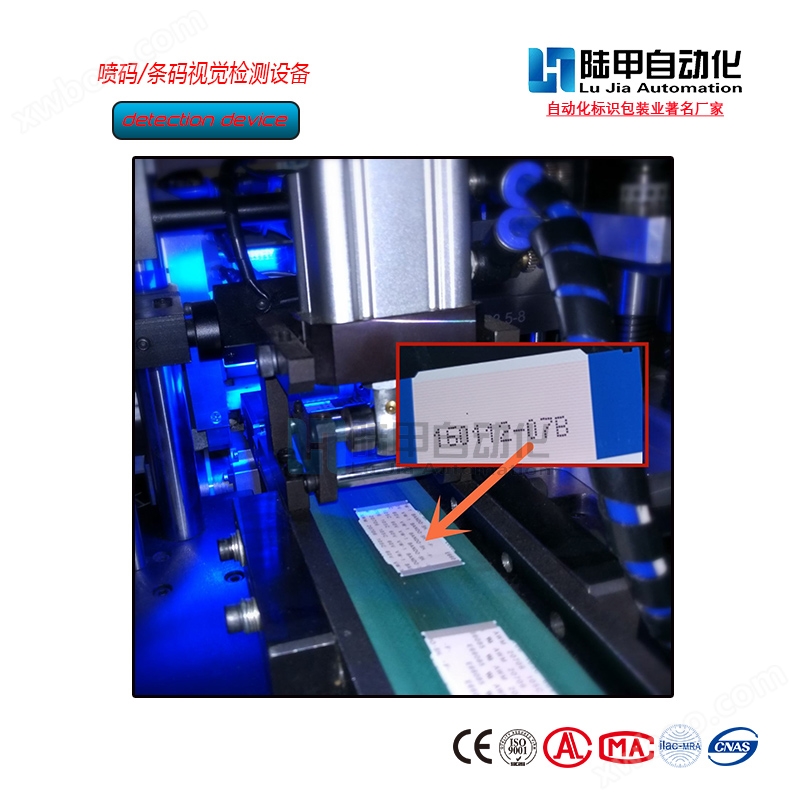

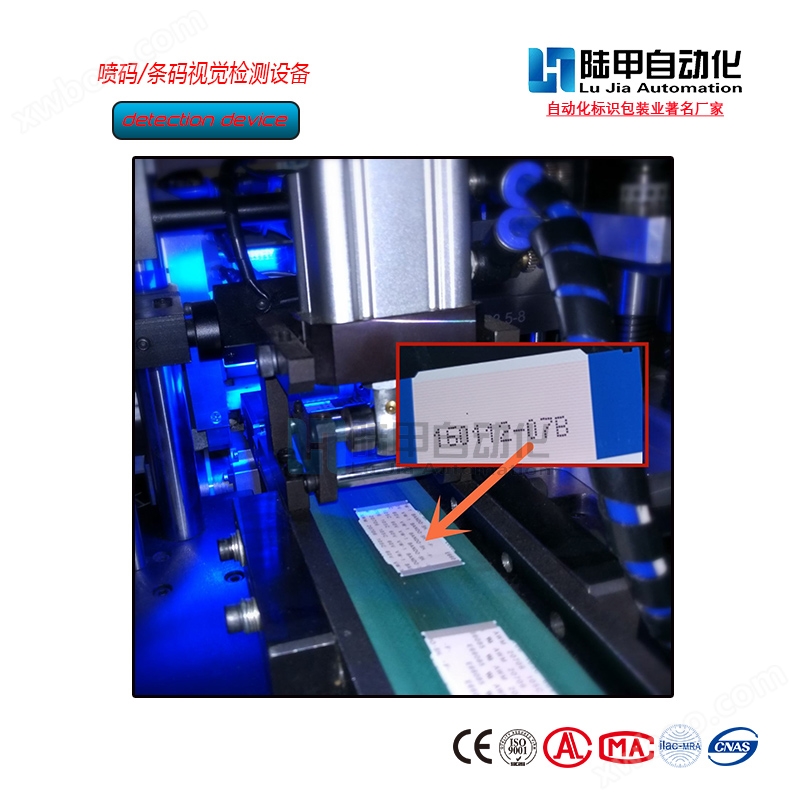

marking/Barcode visual inspection equipment

Basic purpose

SJC-PT barcode visual printingdetectionThe device belongs toOCR Visual Inspection SystemSeries, mainly detecting barcode integrity,markingmachinemarkingIs there any,Check whether the spray code characters are complete, dirty, obstructed, ink dots and other defects,Check if the coding product is correct,Is the date, serial number, etc. correct,Barcode and barcode defect detection, barcode images are divided into cutting method, Fourier transform method, and various barcode defect detection methods;

◆The spray code detection machine is an intelligent guided visual system with a detection speed of up to1500 Beat Per MinuteAdopting a non-contact online detection method, the detection principle is based on internationally synchronized intelligent vision technology, approaching human judgment ability. The system mainly consists of a spray code detection unit, a human-machine interface, and a remover. The coding detection unit is a high-definition and fast camera device; The human-machine interface consists of a touch screen, tower lights, and an operation interface; The eliminator is the executing mechanism of the system, used to divert or remove non-conforming cans;

◆When the device is running, when the tested product passes under the detector, the high-definition camera quickly recognizes whether the code sprayed above the tested product is consistent with the pre stored correct code. Through software processing, it can determine whether the code is qualified, and then remove the unqualified bottles from the bottle flow based on the judgment result. The system can achieve different functions according to different detection requirements, using intelligent learning tools and simple operation settings, so that anyone can quickly master the settings and applications. Just set qualified products, the machine can automatically determine defective products;

◆This device can detect products without codes or with incomplete or missing codes15%), shrink the spray code characters into a ball, offset the spray code position (some spray to the edge of the bottle)And barcode defects. Barcode integrityWaiting for the situation;

Basic equipmentparameter

◆External dimensions:1500 * 850 * 2200 (length * width * height)

◆External power supply:Ac220v (single item)

◆Detection speed:1500Bpm/Min

◆Transmission speed: conveyor belt≦30M/Min

◆External gas source:0.5Mpa

◆External gas source flow rate:>500L/Min

◆External enterprise interface: outer diameter10 trachea

◆Exclude gas volume:≈ 0.01L/time (at 0.4Mpa)

◆Power:0.5Kw

◆Temperature:0℃-45℃

◆Humidity:10%-80%

◆Note: Non standard customization is acceptable